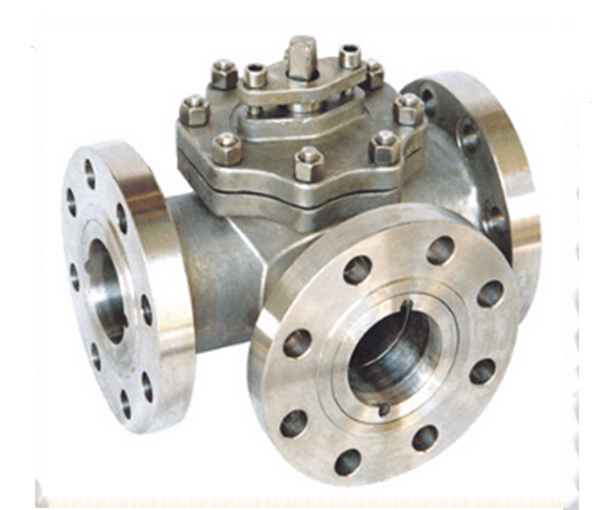

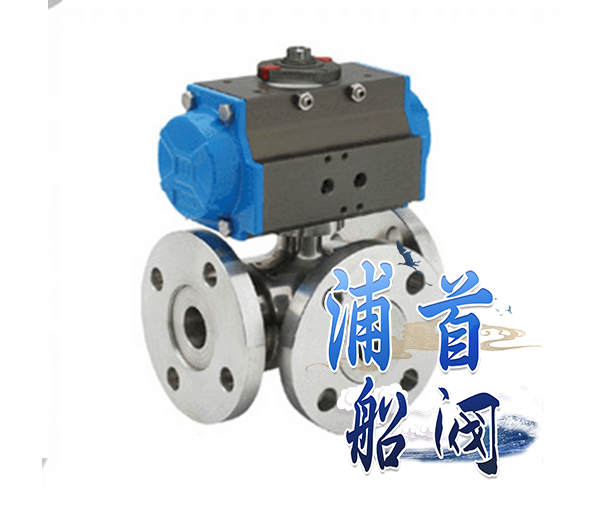

As a large industrial country in China, the traditional industry of valves has been constantly developing, and the types of valves are cumbersome. Stainless steel three-way ball valve is favored by consumers because of its advantages of low fluid resistance, simple structure, small size, light weight, wide application range and so on. The following are some performance characteristics and working principles of stainless steel three-way ball valve.

Structural characteristics of stainless steel three-way ball valve:

Top-mounted structure: the valve installed on the pipeline can be directly inspected and repaired online, which can effectively reduce the device shutdown and reduce the cost. This type of valve should generally be installed horizontally in the pipeline;

Opening and closing without friction: completely solve the problem that the traditional valve affects the sealing due to the friction between the sealing surfaces;

Low torque design. The valve stem with special structure design can be easily opened and closed with only a small handle;

Wedge seal structure. The valve is sealed by the mechanical force provided by the valve stem, pressing the ball wedge onto the valve seat, so that the valve's tightness is not affected by the change in pipeline pressure difference, and the sealing performance is reliably guaranteed under various working conditions;

Single seat design. Eliminates the problem that the medium in the valve cavity affects the safety of use due to abnormal pressure increase;

Self-cleaning structure of the sealing surface. When the ball is tilted away from the valve seat, the fluid in the pipeline passes uniformly through 360 ° along the sealing surface of the ball, which not only eliminates the local erosion of the valve seat by high-speed fluid, but also wash away the accumulation on the sealing surface to achieve the purpose of self-cleaning .

Stainless steel three-way ball valve has the following advantages:

1. The fluid resistance is small, and its resistance coefficient is equal to that of the pipe section of the same length;

2. Simple structure, small size and light weight;

3. Tight and reliable. At present, the sealing surface material of the ball valve is widely used plastic and has good sealing performance. It has also been widely used in vacuum systems;

4. Convenient operation, quick opening and closing, as long as it rotates 90 ° from fully open to fully closed, it is convenient for remote control;

5. Convenient maintenance, the structure of the ball valve is simple, the sealing ring is generally movable, disassembly and replacement are more convenient;

6. When fully open or fully closed, the sealing surfaces of the ball and the valve seat are isolated from the medium, and when the medium passes, it will not cause corrosion of the valve sealing surface;

7. Wide range of application, from small diameter to a few millimeters, to a few meters, from high vacuum to high pressure can be applied.

Link to this article:http://qzlzr.cn/en/xinwenzhongxin/67717.html

Last:How to choose the material of water valve

Next:The working principle and maintenance process of gate valve

Follow the official WeChat

Follow the official WeChat