|

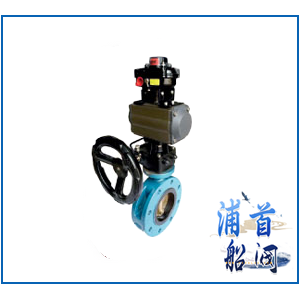

product name:Marine central flange pneumatic butterfly valve

Product caliber:

Product pressure:

product material:

|

Marine central flange pneumatic butterfly valve

OverviewPushou Marine Pneumatic Butterfly Valves are widely used in pipeline systems of ships, ships, cruise ships and marine engineering. Due to the limitations of pipeline space and environment on ships and marine engineering, the operation and environment of ordinary butterfly valves cannot fully meet and adapt to their needs. This product is small in size, has limited space, and can be operated remotely. It can also be connected to the remote control system for remote control operations. For example, when the air supply and power supply on the ship are out of source, this product can also perform butterfly valves on the spot. The opening and closing work, the resource collection of this product is simple and convenient (compressed air), the butterfly valve is sensitive to opening and closing (opening and closing speed 1-3 seconds), the remote control system is equipped with original parts such as opening and closing status signal display, fault alarm and low pressure alarm, etc. Can be connected to the microcomputer through the interface for remote control operations. Pushou products are composed of remote control box, control button, pneumatic drive head, local operation drive mechanism, stroke limit switch, valve body, butterfly plate, valve stem, seat ring and other components. The products can be provided in compliance with ISO standards and JIS standards. And GB standards and various specifications for users to choose. Features

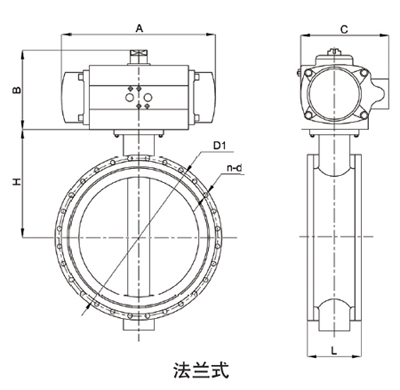

Marine central flange pneumatic butterfly valve GB / T3036-1994, production standards: JIS Japanese standard, DIN German standard, ANSI American standard, GB national standard, CB ship standard, nominal diameter DN50-DN500, nominal pressure PN6-PN16, flange Standard: GB596 GB2501 Body material: cast steel, ductile iron QT450, stainless steel SUS, bronze BZ, valve plate material: stainless steel SUS, bronze BZ, valve seat: nitrile rubber NBR, EPDM, fluoroelastomer FKM.

Standard techniques parameters Nominal diameter: DN40-DN1000 Body material: Ductile iron, 304, 316 Connection method: wafer type, flange type, lug wafer type Pressure level: PN1.0MPa, PN1.6MPa Structure form: midline structure In-valve components Seat seal: EPDM: -30 ℃ ~ 120 ℃ NBR: -30 ℃ ~ 80 ℃ PTFE: -30 ℃ ~ 140 ℃ VITON: -30 ℃ ~ 150 ℃ Valve plate material: Ductile iron nickel plated, nylon coating, aluminum bronze, 304, 316 316L, 1.4529, 2507 Stem material: stainless steel 410, 304 Applicable medium: water, liquid, gas, oil, powder, steam, acid and alkali corrosive medium.

Pneumatic actuators Double-acting: Ventilation on, ventilation off Single-acting gas-opening type: ventilation open, air cut-off, gas source failure closed Single-acting gas-closed type: ventilation closed, air cut-off open, gas source fault open Optional accessories: Reversing solenoid valve, limit switch, air filter pressure reducing valve, electric positioner, handwheel mechanism, position retaining valve Electrical part can choose explosion-proof

Standard related downloads: |

Follow the official WeChat

Follow the official WeChat